Application and principle of three eccentric hard seal butterfly valve

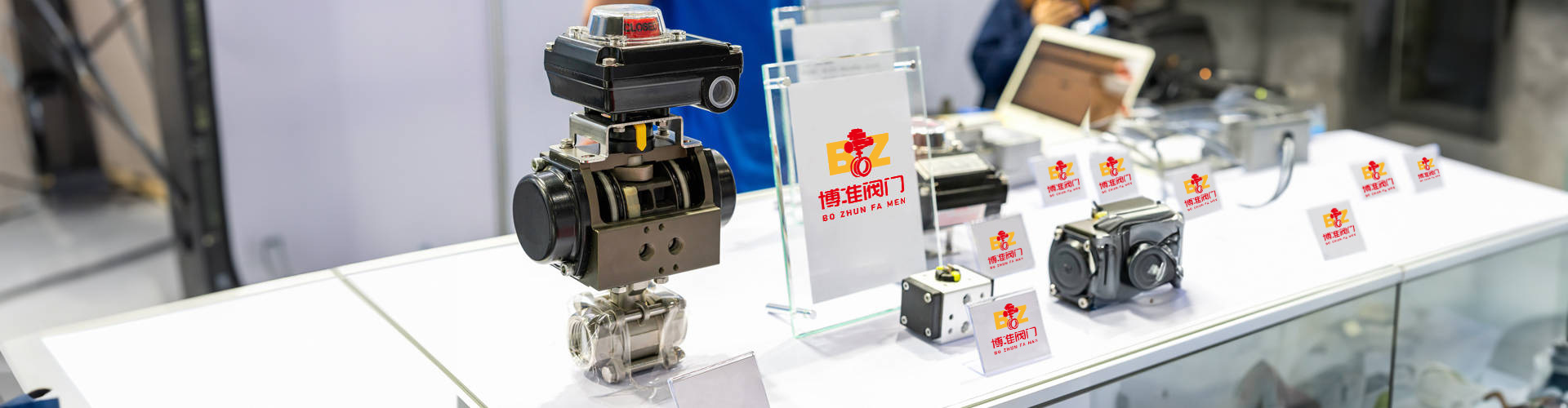

Pneumatic hard seal butterfly valve structure is composed of imported pneumatic piston actuator and three core hard seal butterfly valve, commonly known as pneumatic three eccentric gold flexible seal butterfly valve. The valve seat adopts hard seal compatible multi-level structure, exquisite processing and advanced technology. Pneumatic hard seal butterfly valve and electric valve positioner, input 4~20mADC signal and 0.4 ~ 0.7mpa gas source can control the operation, can realize the adjustment of pressure, flow, temperature, liquid level and other parameters. The pneumatic hard seal butterfly valve is equipped with a travel limit switch, an electric touch valve, a pressure reducing valve and a 0.4-0.7mpa air source, which can realize the switch operation and send two pairs of passive contact signals to indicate the valve switch. Hard seal butterfly valve for three eccentric gold bending sealing structure,

06

2023

/

11

Common causes of valve leakage

Gate valve is one of the most common industrial valves, widely used in petroleum, petrochemical, power plants, long-distance pipelines and shipbuilding and other industrial fields. As a fluid control equipment, the gate valve opening and closing part is a gate, which switches the opening and closing state through the up and down movement of the gate, so as to realize the function of cutting off or connecting the medium in the pipeline. If the gate valve leaks, it is easy to bring hidden dangers to the pipeline and equipment facilities, and even affect the safety of personnel life and equipment safety. Understanding the structure and operation principle of the gate valve can help us to operate the gate valve correctly and better grasp the operation state of the gate valve. Once the gate valve leaks, the first time to take the right way to deal with, reduce economic losses, reduce the probability of accidents. Gate valve leakage is generally divided into internal leakage and external leakage, resulting in more reasons for the leakage of the gate valve, the need for in-depth analysis and research, in order to take appropriate measures to deal. 1. Causes of gate valve leakage 1.1 wedge seal ring machining accuracy is low, resulting in the valve leakage Wedge seal can be divided into two categories, the first hard seal, also known as the metal wedge ring; the second is the soft seal, also known as the composite graphite wedge ring. If the accuracy of the wedge seal ring is low, it is easy to cause leakage in the gate valve. Internal leakage of gate valve due to unstable operation condition of 1.2 production The operating conditions of the valve during production and operation are not stable, and its pressure and ambient temperature may change greatly, which makes the sealing ring bear greater impact pressure, erosion force and deformation, resulting in the gap between the sealing ring and the valve body becoming larger and larger, resulting in internal leakage of the valve. Internal leakage of gate valve due to poor maintenance quality of 1.3 valve Staff to open the valve for maintenance in the process, the installation of the wedge seal ring when the sealing surface is not cleaned, leaving some small particles and impurities, these small impurities in the valve operation process may scratch the sealing surface, once the sealing surface to form a penetrating scratch, it will cause the valve leakage. Internal leakage of gate valve due to corrosion of wedge-shaped sealing ring by 1.4 medium In the design of the wedge seal ring when the need to pay more attention to the strength and corrosion resistance of the seal ring, the surface hardness of the seal ring than the valve cover seal layer is smaller, but also in line with the external force conditions can occur under the action of plastic deformation, long time running process medium may also corrode the wedge seal ring, resulting in gate valve leakage. 1.5 gate valve actuator switch is not in place resulting in internal leakage of gate valve The gate valve switch is controlled by the actuator. The actuator relies on liquid, gas, electricity or other energy sources and converts it into a driving effect through a motor, cylinder or other device to drive the valve to a fully open or fully closed position. If the actuator is not opened or closed properly, the gate valve cannot be opened or closed completely, resulting in internal leakage of the valve. 1.6 valve body defect causing valve leakage Casting valve body often appear casting defects, such as: pores, slag, cracks, sand holes, etc., if these defects in the factory has not been found, or found not to take the correct repair measures, in the field use of the process will appear valve leakage.

06

2023

/

11