Twin screw valve

Twin screw valve structure advantage 1. Compact and short, simple structure, easy to transport. 2. Light weight, simple installation, easy maintenance. 3. Parts reduction, parts cost reduction, suitable for the public group. 4. High output accuracy, no noise, stable effect and long service life. 5. Simplify the structural design, facilitate diversified improvement and upgrading, and adapt to more industry conditions.

Keywords: valve, ball valve

Category:

High precision control valve

Twin screw valve

Introduction and structural advantages of twin screw valve

Main features

The two-component dispensing screw valve is a pump type specially developed according to the dispensing and glue filling process in the electronic industry. It is mainly used for controlling the mixing ratio of two-component liquids. Users can control the flow rate of the conveying medium according to the control motor rotation speed to form a certain proportion difference. The two media will be evenly stirred in the mixing pipe at the discharge end to prevent the mixing glue from solidifying and difficult to clean in the pump body. The double-group dispensing screw pump replaces the traditional pneumatic dispensing valve and can be directly installed on the manipulator arm of the equipment, saving space and cost for the automation equipment.

Twin screw valve structure advantage

1. Compact and short, simple structure, easy to transport.

2. Light weight, simple installation, easy maintenance.

3. Parts reduction, parts cost reduction, suitable for the public group.

4. High output accuracy, no noise, stable effect and long service life.

5. Simplify the structural design, facilitate diversified improvement and upgrading, and adapt to more industry conditions.

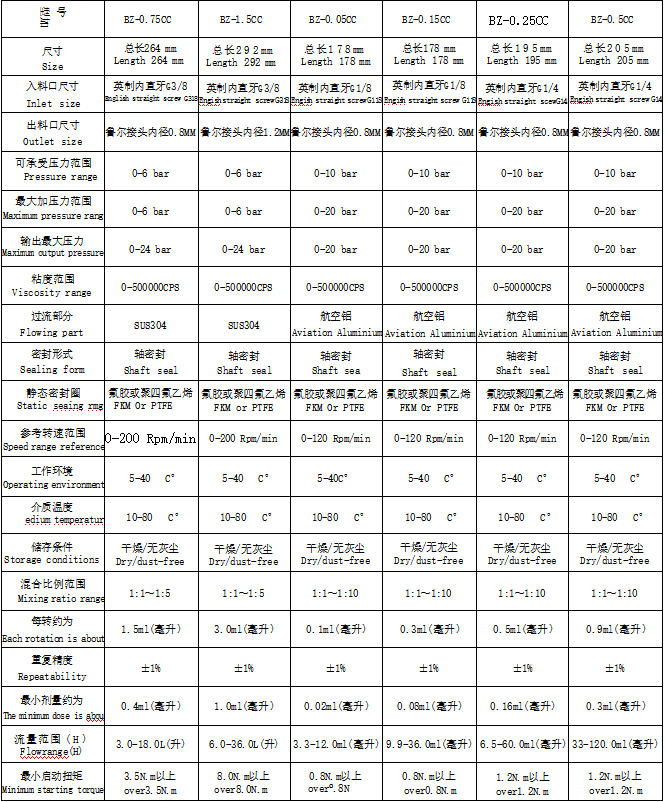

Selection of Twin Screw Valve

Related Products

Product Consulting