VCR connector

The VCR connector has a high purity metal-to-metal seal that provides leak-free service from vacuum to positive pressure.

Keywords: valve, ball valve

Category:

Valve Fittings

VCR connector

Product introduction and features:

The VCR connector has a high purity metal-to-metal seal that provides leak-free service from vacuum to positive pressure.

The seal on the VCR assembly is completed when the gasket is compressed by the flanges on both sides during engagement of the externally threaded nut or fitting body hex with the internally threaded nut.

Side-load bearing shim for easy installation with minimum clearance for removal

Test ports on two locations for easy leak testing

The average roughness of the standard surface polishing on the nozzle and joint body is 10in.(0.25 μm)Ra.

The internal thread has been silver plated to prevent wear and ensure consistency in assembly and construction

The VCR connector design has been helium leak tested and has a maximum leakage rate of <1 E-9mbar * L/s \and a maximum leakage rate of <1 E-9mbar * L/s \when using an uncoated gasket \. Equivalent to a welded joint and available with ultra-high purity cleaning options.

Main applications:

VCR products are mainly used in semiconductor chips, chemical industry, electronics, food, pharmaceutical, panel, photovoltaic, UHV, major power equipment, new energy and aerospace and other strategic emerging industries, suitable for H2/N2,NH3/ASH3,PH3, CF4, SF6, Ar, CL2, BCL3 and other special gases.

Installation Schematic

Installation method:

Preparation: Two set wrench tools, VCR fitting assembly (including internal and external threaded nuts, VCR nipples and gaskets). For high-purity applications, dust-free gloves should be worn before installation and implemented in a clean environment.

1. Set the external thread nut and the internal thread nut into the VCR connecting pipe respectively.

2. Weld the two-part VCR nipple with inner and outer threaded nuts to the sleeve

3. Install metal gasket:

If the shim with support is selected, it is recommended to clamp the shim directly on the VCR nozzle with external thread pendulum nut, so as not to scratch the end face of the nozzle);

If it is an unsupported gasket, the gasket can be directly placed into the VCR nozzle containing the inner silver grain silver mother.

4. Tighten the VCR internal and external threaded nuts by hand.

5. Mark straight lines on the hexagon heads of the inner and outer nuts with a non-sitting oil marker.

6. Use a fixed wrench to fix the external thread nut, and another fixed wrench is clamped into the internal thread nut and rotated clockwise to install it in place (NI nickel/SS stainless steel gasket is locked 1/8 turn, Cu copper material is locked 1/4 circle).

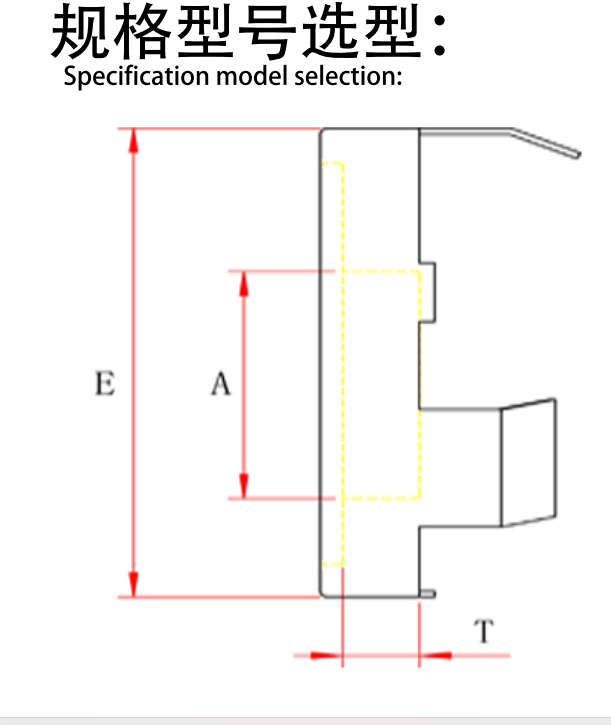

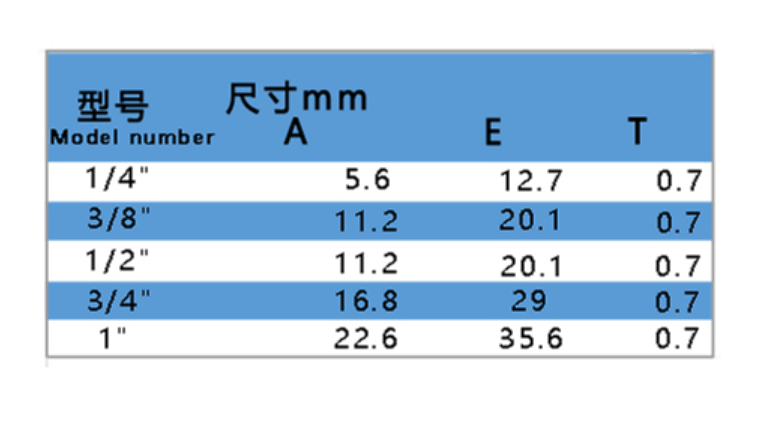

specifications model selection:

Model size:

INSTALLATION CHECK

Inspection after installation

If the VCR connector is not tightened in place during installation, it may cause potential safety hazard

After the installation is completed, the driver can be checked as follows:

1. Check whether the marking angle on the internal and external thread nuts of the VCR meets the installation angle standard (stainless steel/gasket, 45 degrees, bright sheet, 90 degrees) and observe whether the gasket is installed in the test hole on the internal thread nut. These inspection methods are simple and easy, but they need to be marked during construction to reduce the trouble of reloading if the subsequent leak test fails.

2. Positive pressure holding test or vacuum ammonia leak detection check the drain hole on the VCR connector to ensure that the pipeline has no leak.

3. After passing the leak test, important pipelines shall be marked, and VCR joint setting device shall be installed for pipelines with vibration to prevent vibration from loosening.

Installation Precautions

1. After tightening the VCR connector by hand, mark the inner and outer pattern nuts with a marker pen to facilitate inspection after installation.

2. When installing, strictly follow Swagelok's instructions on the number of installation turns, and do not over-protect for leakage, because it will damage the end face of the nozzle, resulting in leakage or reducing the number of uses.

3. When tightening the VCR joint, do not rotate the external screw nut or body, fix the external thread nut or body, and rotate the internal thread nut. The wrench must be screwed inward to form a small included angle to avoid sudden loosening due to joints or shaking hands.

4. Before installing the pipe, remove the stress and keep it on the same axis. Adjust the appropriate angle and tighten it by hand first, then rotate it to the corresponding circle with a wrench. Therefore, do not tighten it directly with a wrench, otherwise the thread will be damaged.

5. Do not loosen and tighten the VCR connector under pressure in the pipeline, unless it is necessary to ensure that the pipeline nitrogen positive pressure is installed.

6. VCR joint components (body, nozzle, nut, gasket, etc.) of different brand materials cannot be mixed.

7. In high-purity applications, it is necessary to ensure that the surface of the VCR nozzle is clean. The inner packaging plastic bag can only be disassembled during installation. The installation process should avoid scratching the surface, especially the sealing surface of the nozzle. To protect the open nozzle, the plastic cap can be used.

8. When reinstalling the VCR connector, a new gasket must be replaced.

Related Products

Product Consulting