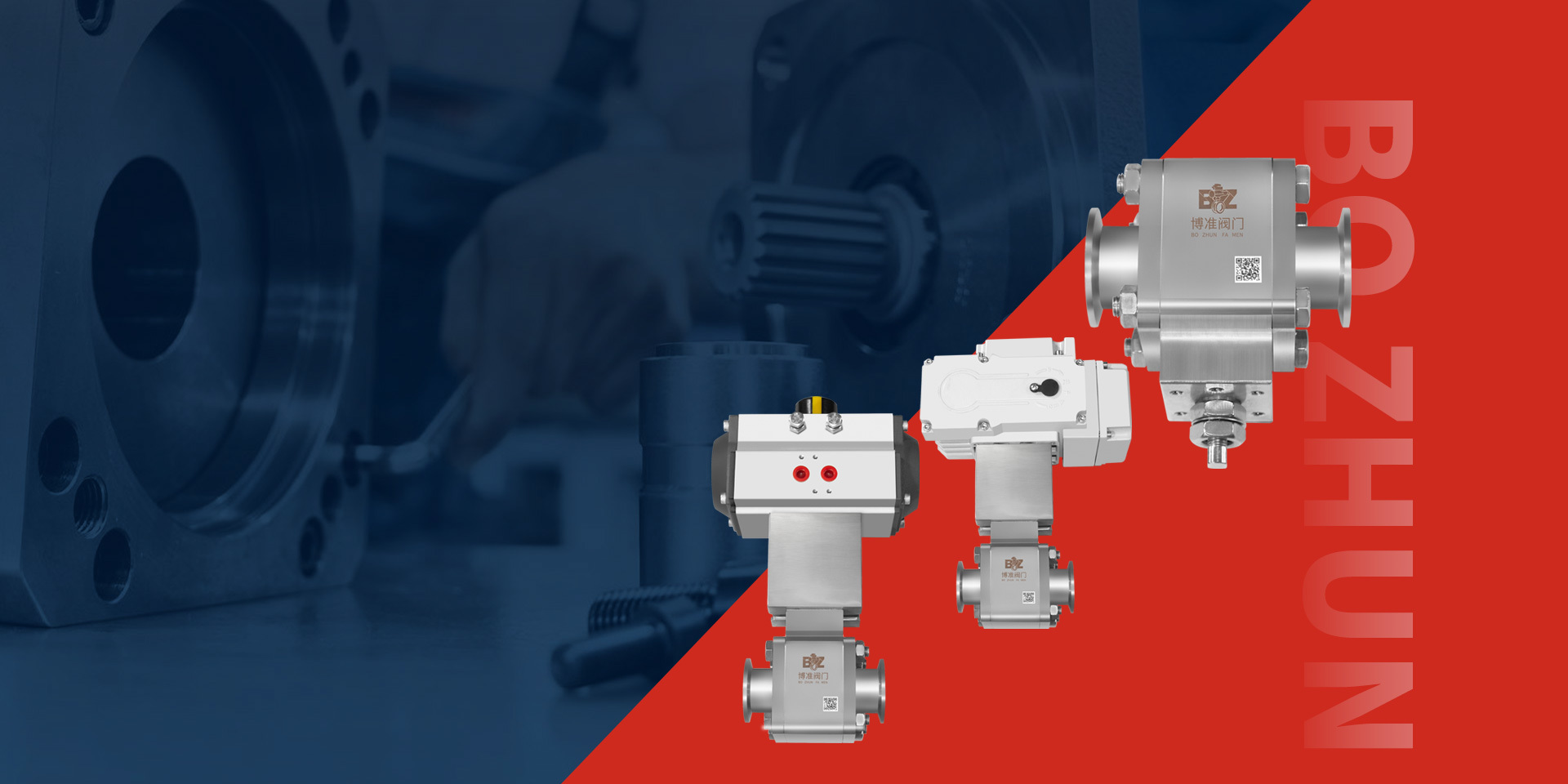

BO ZHUN FA MEN

Xiamen Bozhun Valve Co., Ltd.

Specializing in high-end control valve scientific research design, manufacturing, sales

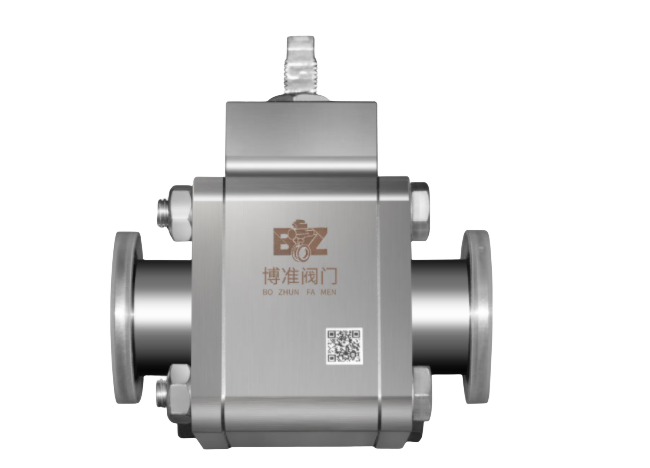

Xiamen Bozhun Valve Co., Ltd. is an international entity enterprise specializing in the scientific research, design, manufacturing, sales, technical exchange and import and export trade of high-end control valves. The company's vibrant corporate vitality and team spirit have attracted a group of technical elites and experienced production and sales personnel who have been engaged in product research and development for a long time in the industry, and have accumulated rich experience in product development, production and marketing for the company. Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Company establishment

Plant area

Customer Service

Solution

semiconductor electronics

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Food

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Pharmaceutical

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Chemical

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Electricity

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Energy

Our company adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, relies on science and technology for innovation and the technical system with independent intellectual property rights as the core is our backbone.

Partners

Technical Services

Xiamen Bozhun Valve adheres to the traditional Chinese craftsman spirit, absorbs the rigorous manufacturing concept of Germany, and constantly innovates and innovates in the process of inheritance, enriching the cultural heritage and technical content of the enterprise.

View more